test

A 3D printer is a technology that uses an additive manufacturing process to create tangible objects from digital designs by adding material layer by layer. This process is called "Additive Manufacturing" and it builds 3D objects by layering materials, similar to constructing a building from the ground up.

Using a 3D printer starts with having a 3D model file, which can be created using 3D design software or by using a 3D scanner to convert real-world objects into digital files. Once the model file is ready, a program called a "Slicer" is used to set various parameters and select the material to be printed. The Slicer program calculates and slices the 3D model into layers, converting the information into a format that the printer can understand.

The printer then prints layer by layer, starting from the first layer to the final layer. The materials used can be plastic, powder, or liquid, depending on the technology and application.

Currently, there are several 3D printing technologies being developed, such as:

3D printers began development in 1983, but they were not widely adopted initially due to high costs and patent restrictions. Today, this technology has become widely popular and more affordable.

If you want to purchase a 3D printer, consider the type of work you need to do, the materials you want to use, and your budget. Currently, there are various types of 3D printers available, such as those for prototyping, manufacturing parts, or even creating art.

3D printing technology is a revolutionary advancement in the manufacturing industry, and it is expected to continue evolving and improving in the future. For instance, the development of simultaneous multi-layer printing could drastically transform manufacturing processes.

Machine Tech Co., Ltd.

Phone: 081-6830289, 084-1425321

Engineers and entrepreneurs need to consider manufacturing methods in the process of designing parts. Each method has its own strengths and weaknesses, and production costs are a crucial factor in decision-making. Therefore, selecting a manufacturing method requires evaluating various aspects to achieve maximum efficiency and cost savings.

There are three main manufacturing processes in the industry:

This article will focus on formative manufacturing.

Formative manufacturing is a process commonly used to produce large quantities of parts. The main investment is in creating tools and molds during the initial phase. Although the initial investment is high, it allows for mass production at a rapid pace, reducing the cost per unit. This process is ideal for applications requiring speed and high-volume production.

Mass production that competes on cost is well-suited to this process. However, formative manufacturing has its limitations. The creation of tools and molds is expensive and complex, requiring significant time and resources initially. Achieving cost-effectiveness necessitates a large production volume.

Tool design in this process must consider complexity and details such as angles, shapes, forms, and the thickness of both the parts and molds. Effective design requires skill and experience to ensure high-quality parts and cost efficiency.

Formative manufacturing is a highly efficient process for producing large quantities of parts with a low cost per unit. However, it requires substantial initial investment in tools and molds. The ability to design effectively and understand the manufacturing process is crucial for smooth and efficient production.

Reference:

The 3D Printing Handbook by Ben Redwood, Filemon Schoffer, Brian Garret

Machinetech Co., Ltd.

Contact 3D Printer Department: 081-6830289, 084-1425321

Here is the article translated into English:

Formative Manufacturing: A Technology Revolutionizing Industry

In the world of manufacturing, efficient and cost-effective production methods are crucial considerations for engineers and entrepreneurs. One of the most popular manufacturing methods is Formative Manufacturing, which is suitable for mass production with low long-term costs.

What is Formative Manufacturing?

Formative Manufacturing is a production process that uses pressure or force to shape materials into desired forms using molds or special tools. This method is suitable for mass production as it can produce quickly and has a lower cost per unit than other methods.

Popular Formative Manufacturing Techniques

Advantages of Formative Manufacturing

Key Benefits

Current Challenges of Formative Manufacturing

Formative Manufacturing vs 3D Printing

While Formative Manufacturing is suitable for mass production, 3D printing excels in flexibility and producing highly complex parts without the need for molds.

Advantages of 3D Printing:

Combined Usage:

In modern industry, Formative Manufacturing and 3D printing are often used together to increase production efficiency, such as:

Conclusion

Formative Manufacturing remains a core technology in the manufacturing industry, especially for mass production. However, integrating 3D printing technology with traditional manufacturing processes is opening up new opportunities to increase efficiency and reduce production costs. Entrepreneurs who can leverage both technologies will have a competitive advantage in the modern industrial era.

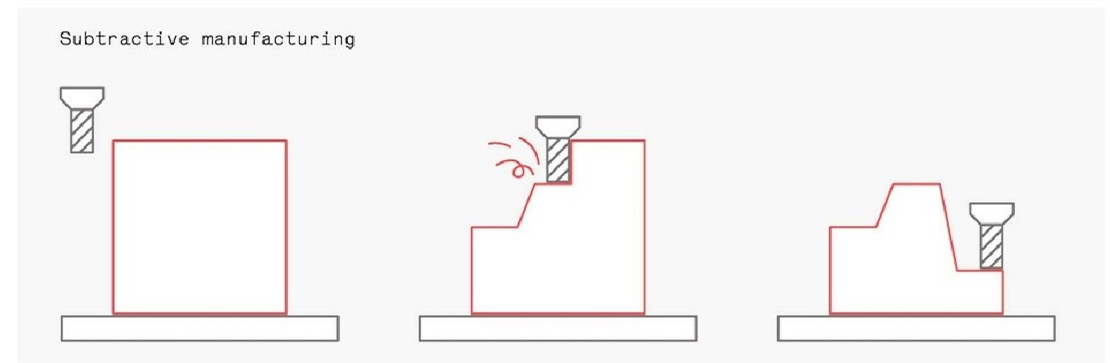

In the world of modern industrial manufacturing, Subtractive Manufacturing stands as a critical production technology. Today, Machine Tech will guide you through this fascinating manufacturing method.

Subtractive Manufacturing is a production process that begins with a solid material and gradually removes unwanted material using cutting tools, ultimately creating the desired component. This process employs various cutting tools and machines, including:

This process can create parts with exceptional accuracy and surface finish. The quality of the final product depends directly on the machinery and tools used.

Capable of working with a wide range of materials, including metals, plastics, and other substances.

Leading manufacturing facilities are increasingly adopting 5-Axis CNC machines because they:

Subtractive Manufacturing is crucial in industries such as:

Subtractive Manufacturing represents a sophisticated production technology characterized by precision, quality, and flexibility. Its ability to create complex, high-tolerance parts makes it an indispensable method in modern manufacturing.

Reference: The 3D Printing Handbook by Ben Redwood, Filemon Schoffer, Brian Garret

© 2022 Machine Tech Co., Ltd. All Rights Reserved. Web design by 1001click.