• Very high precision with 0.1 micron linear optical encoder system

• Highly rigid structure with low mass bridges and carriages

• Vibration isolation of table and gantries

• Tilt-A-Jet cutting head for fast cutting with taper elimination

• All components have matched thermal expansion

• Equipped with 7/15 Mini MAXJET® 5 Nozzle

• Revolutionary patent-pending process for fine abrasive feed rate

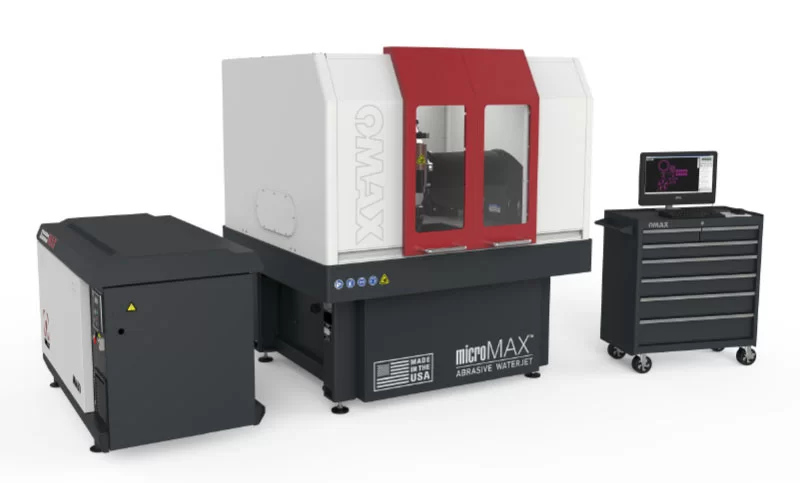

• Full enclosure with environmental controls

• Advanced pressure controls for piercing delicate materials

• Machines a wide range of materials with high accuracy

• No heat-affected zones or mechanical stresses

• Leaves behind a satin-smooth edge, reducing secondary operations

• Stiff construction greatly reduces vibration and increases accuracy

• Easily cut non-conductive and reflective materials

• Can machine hardened steel as easily as annealed steel

• Full enclosure provides quiet and clean operation below 80db