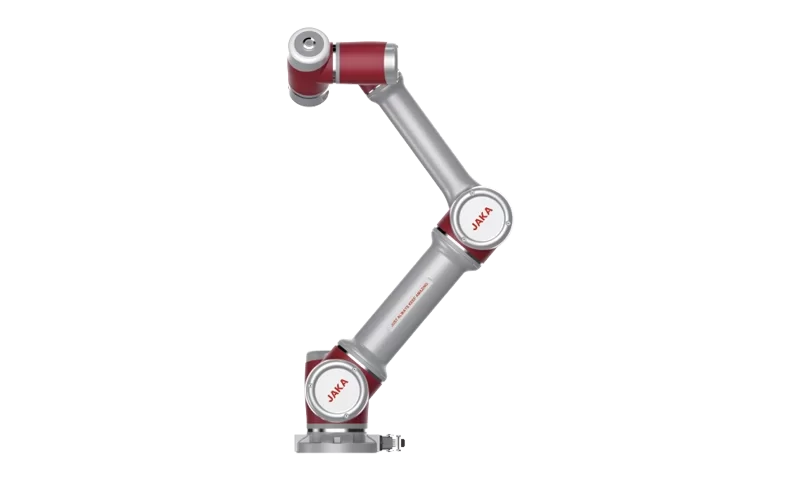

Product Features:

Labor Cost Reduction: Utilizing JAKA Cobots in the manufacturing process reduces the need for human labor, resulting in cost savings in labor hiring and wages.

Increased Production Efficiency: JAKA Cobots can work continuously 24/7 without breaks and exhibit high precision, leading to continuous and more efficient production processes.

Reduced Losses and Errors: The accuracy of JAKA Cobots in performing tasks helps minimize errors that may occur with human labor, such as force application or calculation errors, reducing raw material losses and the time needed to rectify mistakes.

Adjustability and Versatility: JAKA Cobots can adjust their size and exhibit versatility in their operations, allowing them to arrange and manage tasks in limited spaces. This makes them suitable for various industries and manufacturing processes.

Safety: JAKA Cobots are designed with safety in mind for collaborative work with humans. They incorporate detection technology and halt operations upon detecting any unexpected human presence.

Incorporating JAKA Cobots into the manufacturing process not only promises increased efficiency and precision but also contributes to a safer and collaborative working environment.