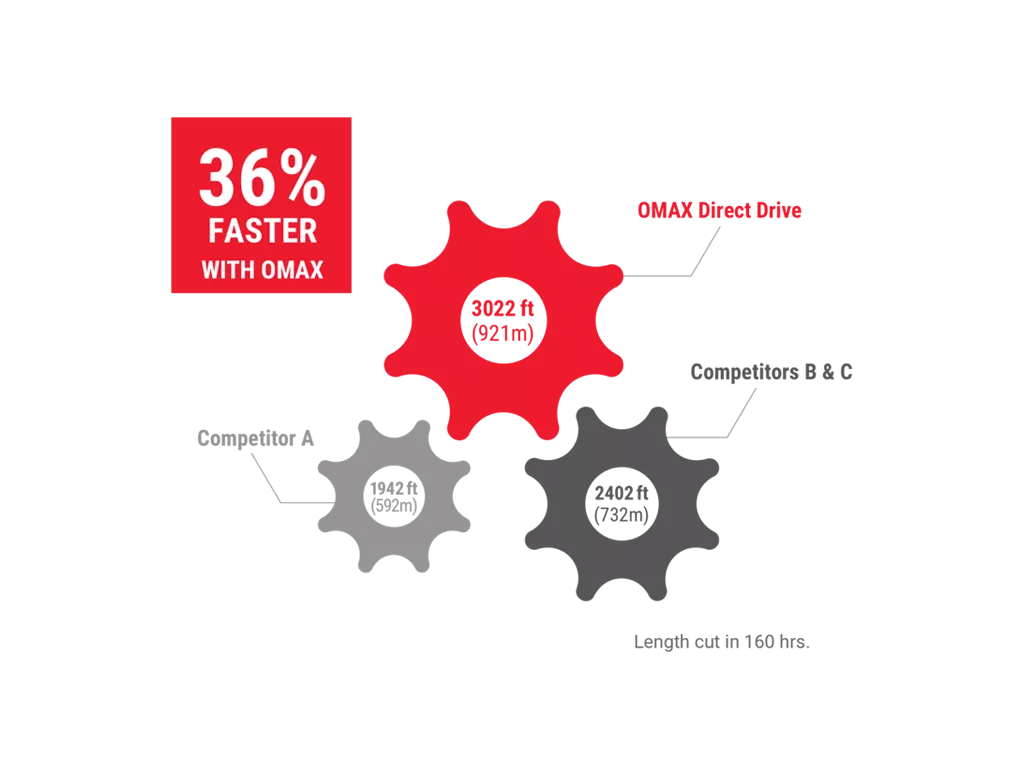

OMAX’s direct drive pumps are the most efficient pumps on the market. With the same configuration in pressure and motor horsepower, higher efficiency pumps lead to an increase in cutting speed, resulting in less production cost and increased output.

For an in depth look at how OMAX Pump Technology stacks up against the competition read the white paper.

Direct drive pumps don’t use hydraulic oil, so there is no need for costly chemical disposal when conducting maintenance. Also, the water and power consumption of a direct-drive pump is significantly less than other types of waterjet pumps.

All OMAX Direct Drive Pumps are compact, quiet, efficient, easy to maintain and inexpensive to operate.

| Pump Type | Pressure (KSI) | Orifice (in.) | Hydraulic HP | Efficiency |

|---|---|---|---|---|

| OMAX ENDUROMAX | 60 | 0.016 | 41.9 | 83.8% |

| Competitor A | 87 | 0.01 | 28.6 | 57.2% |

| Competitor B & C | 60 | 0.014 | 32.1 | 64.2% |

| Based on manufacturer recommended configuration | ||||

Built with the same dedication to waterjet ingenuity as our renowned direct drive pumps, the OMAX DynaMAX pump allows for more possibilities in your waterjet cutting. The intensifier pump is perfect for water only (or pure waterjet) applications, multi-cutting head systems and etching.

The DynaMAX series is offered as: DynaMAX 3-Series Intensifier Pump, DynaMAX 5-Series Predictive Intensifier Pump, DynaMAX 5-Series Dual Intensifier Pump.

The DynaMAX line of pumps maintains a 500-hour maintenance cycle.

© 2022 Machine Tech Co., Ltd. All Rights Reserved. Web design by 1001click.