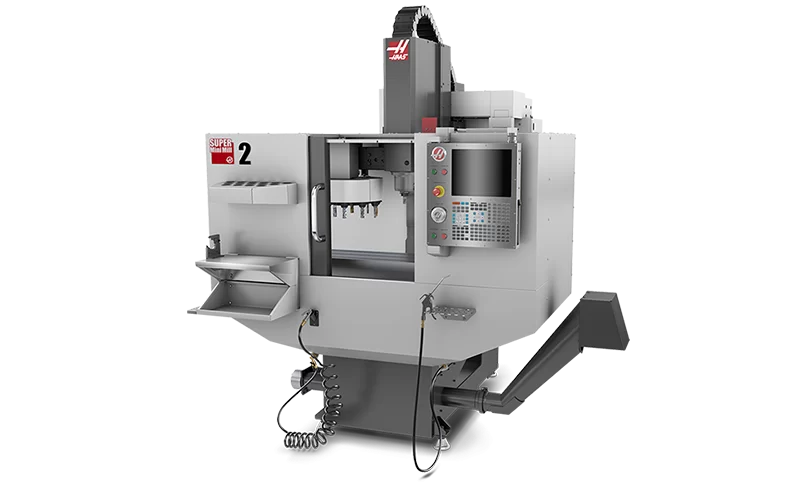

Economical solution for small parts

Compact footprint

Optimal machine for high-volume production

Made in the USA

Haas Mini Mills are the industry standard for compact machining centers.

They provide an economical solution for small parts machining in a compact

package that is loaded with full-size features. The Super Mini Mill 2 is enhanced with a faster spindle and higher rapidsfor improved production output and part finish. It offers the same combination of small footprint, full CNC capabilities,

and affordable price as the standard Mini Mill 2, but with extended

travels. It is perfect for schools, start-up shops, or as a first step into

CNC machining. It is a valuable addition for shops needing a “second-op”

machine, or an additional spindle where space is limited.

© 2022 Machine Tech Co., Ltd. All Rights Reserved. Web design by 1001click.