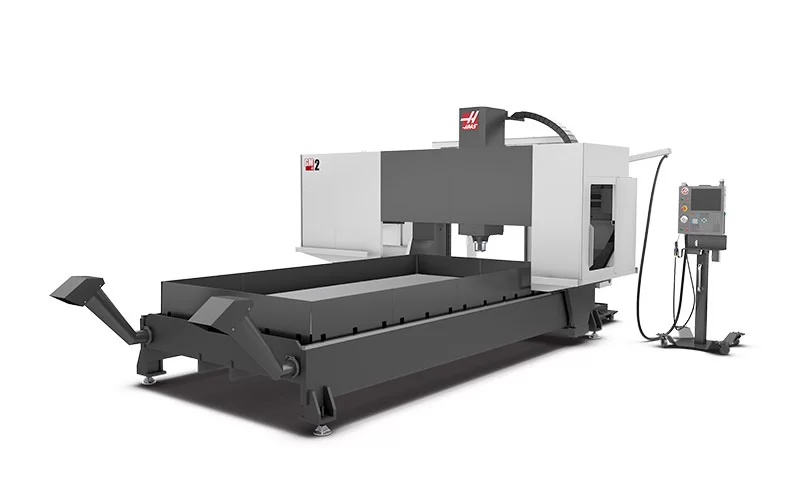

Robust 40-taper inline direct-drive spindle

75" between columns for large parts

Rigid-steel construction

Traveling guard for chip and coolant containment

1" thick aluminum table

Made in the USA

75" between columns for large parts

Rigid-steel construction

Traveling guard for chip and coolant containment

1" thick aluminum table

Made in the USA

Travels

X,Y,Z Axis

: 3,683 x 2,223 x 559 mm

Spindle

Max Rating

: 22.4 kW

Max Speed

: 8,100 rpm

Max Torque

: 122.0 Nm @ 2,000 rpm

Drive System

: Inline Direct-Drive

Taper

: CT or BT 40

Bearing Lubrication

: Air / Oil Injection

Air / Oil Injection

Cooling

: Liquid Cooled

Table

Width x Length

: 1,829 x 3,658 mm

Thickness

: 25 mm

Max Weight on Table (evenly distributed)

: 2,722 kg

Feedrates

Max Cutting

: 12.0 m/min

Rapids on X

: 12.0 m/min

Rapids on Y

: 48.0 m/min

Rapids on Z

: 30.0 m/min

Axis Motors

Max Thrust X

: 20,017 N

Max Thrust Y

: 7,340 N

Max Thrust Z

: 8,896 N

Tool Changer

Type

: SMTC

Capacity

: 30+1

Max Tool Diameter (full)

: 64 mm

Max Tool Weight

: 5.4 kg

General

Coolant Capacity

: 360 L

Air Requirements

Air Required

: 113 L/min @ 6.9 bar

Dimensions-Shipping

Pallet

: 5,740 x 3,890 x 3,230 mm

Weight

: 9,190.0 kg

Electrical Specification

Input Voltage, Amps (3 Phase) - Low

: 220 VAC, 70A

Input Voltage, Amps (3 Phase) - High

: 440 VAC, 35A